The Critical Role of Printed Circuit Board Manufacturers in Todays Electronics

Table of Contents

- The Critical Role of Printed Circuit Board Manufacturers in Today’s Electronics

- The Evolution of PCB Manufacturing

- The Role of PCB Manufacturers in the Electronics Industry

- The Impact of PCB Manufacturers on the Electronics Industry

- Innovation and Advancements

- Meeting the Demands of the Market

- Ensuring Quality and Reliability

- Challenges Faced by PCB Manufacturers

- Cost and Time Constraints

- Environmental Concerns

The Critical Role of Printed Circuit Board Manufacturers in Today’s Electronics

The world of electronics is constantly evolving and advancing, with new technologies and devices being introduced at a rapid pace. From smartphones and laptops to medical equipment and automotive systems, electronics have become an integral part of our daily lives. And at the heart of these electronic devices lies a crucial component – the printed circuit board (PCB).

A PCB is a thin board made of non-conductive material, such as fiberglass, with conductive pathways etched or printed onto it. These pathways, also known as traces, are used to connect electronic components and allow them to communicate with each other. PCBs are essential in the functioning of electronic devices, and their quality and reliability are crucial for the overall performance of the device.

In today’s fast-paced and highly competitive electronics industry, the role of PCB manufacturers has become more critical than ever. They play a crucial role in the design, production, and assembly of PCBs, ensuring that they meet the ever-increasing demands for smaller, faster, and more complex electronic devices. In this article, we will explore the critical role of PCB manufacturers in today’s electronics industry and how they are shaping the future of technology.

The Evolution of PCB Manufacturing

The history of PCBs can be traced back to the early 20th century when they were first used in radios. However, it was not until the 1950s that PCBs became widely used in electronic devices. The early PCBs were made using a labor-intensive process, where the conductive pathways were hand-drawn onto the board. This process was time-consuming, expensive, and prone to errors.

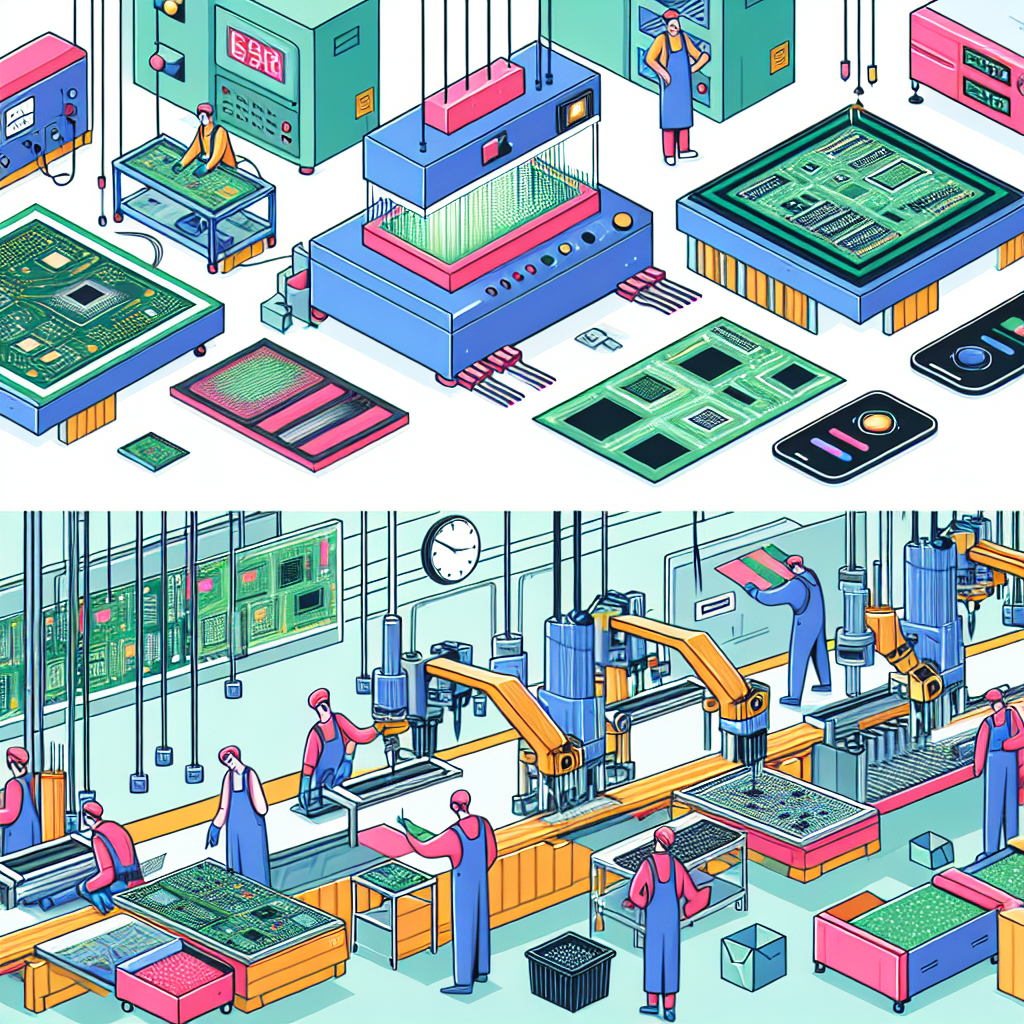

With the advancement of technology, the manufacturing process of PCBs has evolved significantly. Today, PCBs are produced using automated processes, making them more precise, efficient, and cost-effective. The use of computer-aided design (CAD) software has also revolutionized the design process, allowing for more complex and compact PCB designs.

One of the most significant advancements in PCB manufacturing is the introduction of surface mount technology (SMT). SMT allows for smaller and more densely packed components, resulting in smaller and more compact electronic devices. This has been made possible by the use of automated pick-and-place machines that can accurately place tiny components onto the PCBs.

The Role of PCB Manufacturers in the Electronics Industry

PCB manufacturers play a critical role in the electronics industry, and their contributions are often overlooked. They are responsible for producing high-quality PCBs that meet the specifications and requirements of their clients. This involves a complex and multi-step process that requires precision, expertise, and attention to detail.

The first step in the PCB manufacturing process is the design phase. PCB manufacturers work closely with their clients to understand their requirements and design a PCB that meets their needs. This involves selecting the right materials, determining the size and shape of the PCB, and designing the layout of the traces. The use of CAD software has made this process more efficient and accurate, allowing for faster turnaround times.

Once the design is finalized, the next step is the production of the PCB. This involves the use of specialized equipment, such as etching machines, to create the conductive pathways on the board. The quality of the materials used and the precision of the equipment are crucial in ensuring the reliability and performance of the PCB.

After the PCBs are produced, they undergo a series of tests to ensure that they meet the required standards. These tests include checks for continuity, insulation resistance, and functionality. Any defects or errors are identified and corrected before the PCBs are sent for assembly.

The final step in the PCB manufacturing process is the assembly of the electronic components onto the PCB. This is a delicate process that requires skilled technicians and specialized equipment. The components are carefully placed onto the PCB, and then soldered onto the conductive pathways. The use of automated pick-and-place machines has made this process faster and more accurate, resulting in higher quality and more reliable PCBs.

The Impact of PCB Manufacturers on the Electronics Industry

The role of PCB manufacturers goes beyond just producing PCBs. They have a significant impact on the electronics industry and are shaping the future of technology in many ways.

Innovation and Advancements

PCB manufacturers are constantly pushing the boundaries of technology and innovation. They are always looking for ways to improve the production process, reduce costs, and increase the performance of PCBs. This has led to the development of new materials, techniques, and processes that have revolutionized the electronics industry.

For example, the use of flexible PCBs has opened up new possibilities in the design and production of wearable technology, medical devices, and other applications where flexibility is crucial. PCB manufacturers are also exploring the use of new materials, such as graphene, which has the potential to make PCBs smaller, faster, and more energy-efficient.

Meeting the Demands of the Market

The demand for smaller, faster, and more complex electronic devices is constantly increasing. This puts pressure on PCB manufacturers to produce PCBs that can meet these demands. They are constantly investing in new equipment, technologies, and processes to keep up with the ever-changing market trends.

For instance, the rise of the Internet of Things (IoT) has led to an increase in the demand for PCBs that can support wireless connectivity. PCB manufacturers have responded to this demand by developing new techniques, such as embedded antennas, to enable wireless communication on PCBs.

Ensuring Quality and Reliability

With the increasing complexity of electronic devices, the quality and reliability of PCBs have become more critical than ever. PCB manufacturers play a crucial role in ensuring that the PCBs they produce meet the required standards and specifications. This involves rigorous testing and quality control measures to identify and eliminate any defects or errors.

By producing high-quality and reliable PCBs, manufacturers are helping to build trust and confidence in the electronics industry. This is especially important in industries such as healthcare and automotive, where the reliability of electronic devices is crucial for the safety and well-being of individuals.

Challenges Faced by PCB Manufacturers

While PCB manufacturers play a critical role in the electronics industry, they also face several challenges that can impact their operations and the quality of their products.

Cost and Time Constraints

The electronics industry is highly competitive, and manufacturers are under constant pressure to reduce costs and shorten production times. This can be challenging for PCB manufacturers, as producing high-quality PCBs requires time, expertise, and specialized equipment. Any compromise on these factors can result in lower quality and less reliable PCBs.

Environmental Concerns

The production of PCBs involves the use of chemicals and materials that can be harmful to the environment. PCB manufacturers must adhere to strict regulations and guidelines to ensure that their operations are environmentally friendly. This can add to the production costs and can be a challenge for smaller manufacturers who may not have